| brochure_3.pdf | |

| File Size: | 559 kb |

| File Type: | |

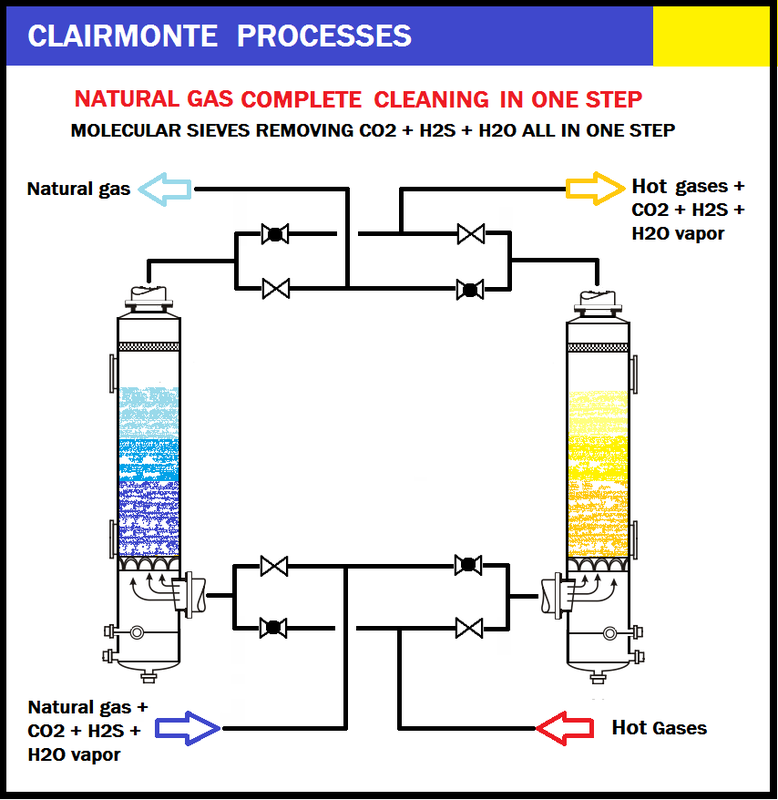

MOLECULAR SIEVES REMOVING H2O VAPOR + CO2 + H2S ALL IN ONE STEP

Clairmonte Processes is proud to be the first to present to the worldwide market Natural Gas Complete Cleaning in One Step; instead of having two separate removal units: one to dehydrate natural gas, next another separation unit to remove CO2 and H2S. These two units can be replaced by one molecular sieve separation unit removing all water vapor, CO2, and H2S in one step, which is much simpler than either of TEG dehydration or ethanolamine removal for CO2 and H2S.

Also both TriEthylene Glycol (TEG) drying unit, and EthanolAmine CO2 and H2S removal unit, they have each a distillation tower to regenerate both TEG and Ethanolamine. The distillation tower will consequently need an air cooler to condense vapors coming at the top, and a reboiler to vaporize the liquid bottoms. Also a distillation tower has bubble caps and trays which are much more complicated than a simple contact drum containing layers of molecular sieves.

Clairmonte Processes is proud to be the first to present to the worldwide market Natural Gas Complete Cleaning in One Step; instead of having two separate removal units: one to dehydrate natural gas, next another separation unit to remove CO2 and H2S. These two units can be replaced by one molecular sieve separation unit removing all water vapor, CO2, and H2S in one step, which is much simpler than either of TEG dehydration or ethanolamine removal for CO2 and H2S.

Also both TriEthylene Glycol (TEG) drying unit, and EthanolAmine CO2 and H2S removal unit, they have each a distillation tower to regenerate both TEG and Ethanolamine. The distillation tower will consequently need an air cooler to condense vapors coming at the top, and a reboiler to vaporize the liquid bottoms. Also a distillation tower has bubble caps and trays which are much more complicated than a simple contact drum containing layers of molecular sieves.